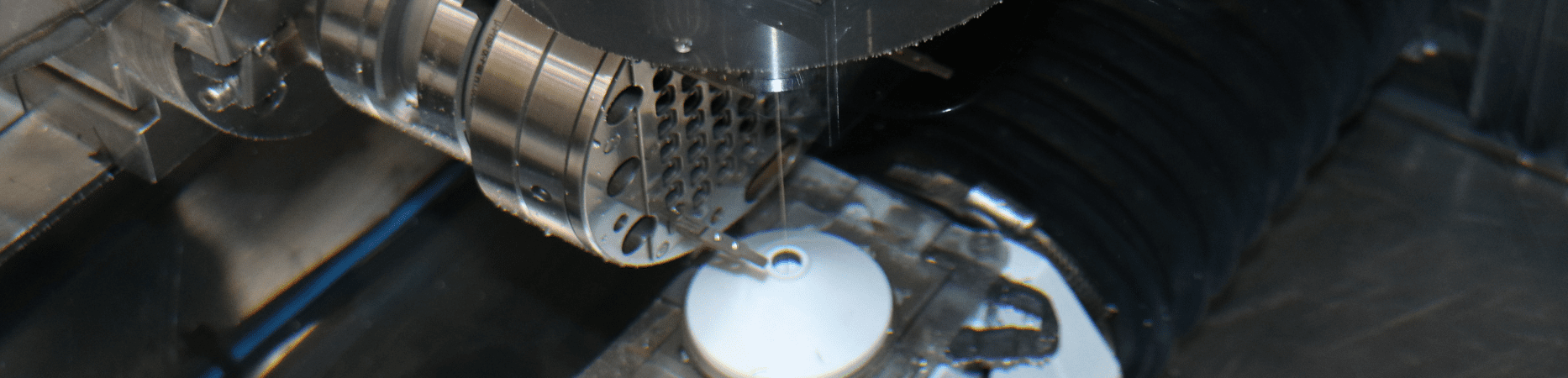

EDM (Electrical Discharge Machining)

When traditional machining hits the limits of what’s technically or economically viable, for example a very small hole or very intricate feature on a part, C&M can use its in-house electrical discharge machining (EDM) capabilities to provide value to its customers. In a testimonial to the way we invest with our partner customers, we saw value for a part. We suggested internalizing what was outsourced and costing the customer far too much. We then purchased our first EDM machine and cut the customer’s EDM costs by more than half!

Request a Quote

CNC SWISS MACHINING SPECIFICATIONS

- Machining Processes

-

- Wire EDM

- Wire EDM

- Materials

-

- Super Alloys

Titanium

Alloy Steels

Stainless Steel

Carbon Steel

Brass - Aluminum

Copper

Delrin

Ultem

All Plastics

- Super Alloys

- Tolerance (+/-)

- ± 0.0001

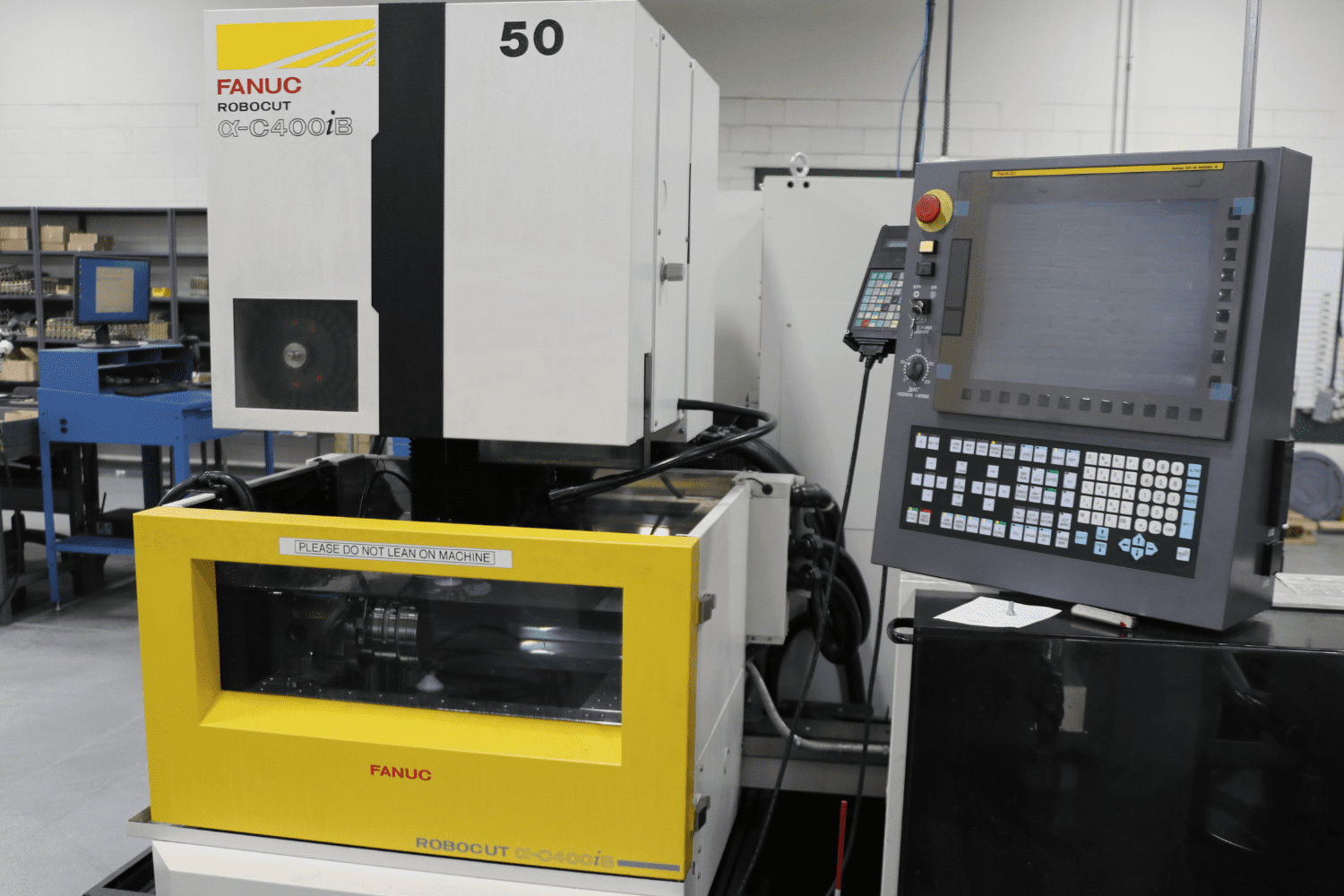

- Equipment

-

- FANUC CIB - X, Y, Z, U, & V Axis (2)

Rotary Table 4th Axis (1)

- FANUC CIB - X, Y, Z, U, & V Axis (2)

- Secondary Services Offered

-

- CAD Design Services

CAM Programming Services

Assembly

Parts Washing - Vapor Degreasing

Laser Marking

Laser Welding - Approved Vendors For:

- Grinding

- Plating

- Passivating

- Heat Treating

- Anodizing

- CAD Design Services

- Production Volume

-

- Minimum 500 parts

Customized Inventory Stocking Programs:- Just In Time (JIT)

- KanBan

- EDI

- Minimum 500 parts

ADDITIONAL INFORMATION

- Industry Focus

-

- Aerospace

Industrial Automation

Medical

Microwave

Electro-Optical/Infrared/Thermal Imaging

Flow Control - Military

Defense

Robotics

Oil & Gas

Semiconductor

- Aerospace

- File Formats

-

- AutoCAD (DWG,DWZ)

DXF

CADL

PDF

SolidWorks (SLDPRT,SLDDRW,SLDDRT) - X_T Parasolid Text

X_B Parasolid Binary

SLDPRT SolidWorks

TPT AutoDesk Inventor

STL ProE STEP

- AutoCAD (DWG,DWZ)