CNC Mill-Turn Machining

At C&M Precision Tech, we are a leading provider of high quality CNC mill-turn machining services to a diverse mix of demanding industries. With an energetic staff of technically astute manufacturing professionals, we can handle complex production jobs while meeting firm delivery commitments.

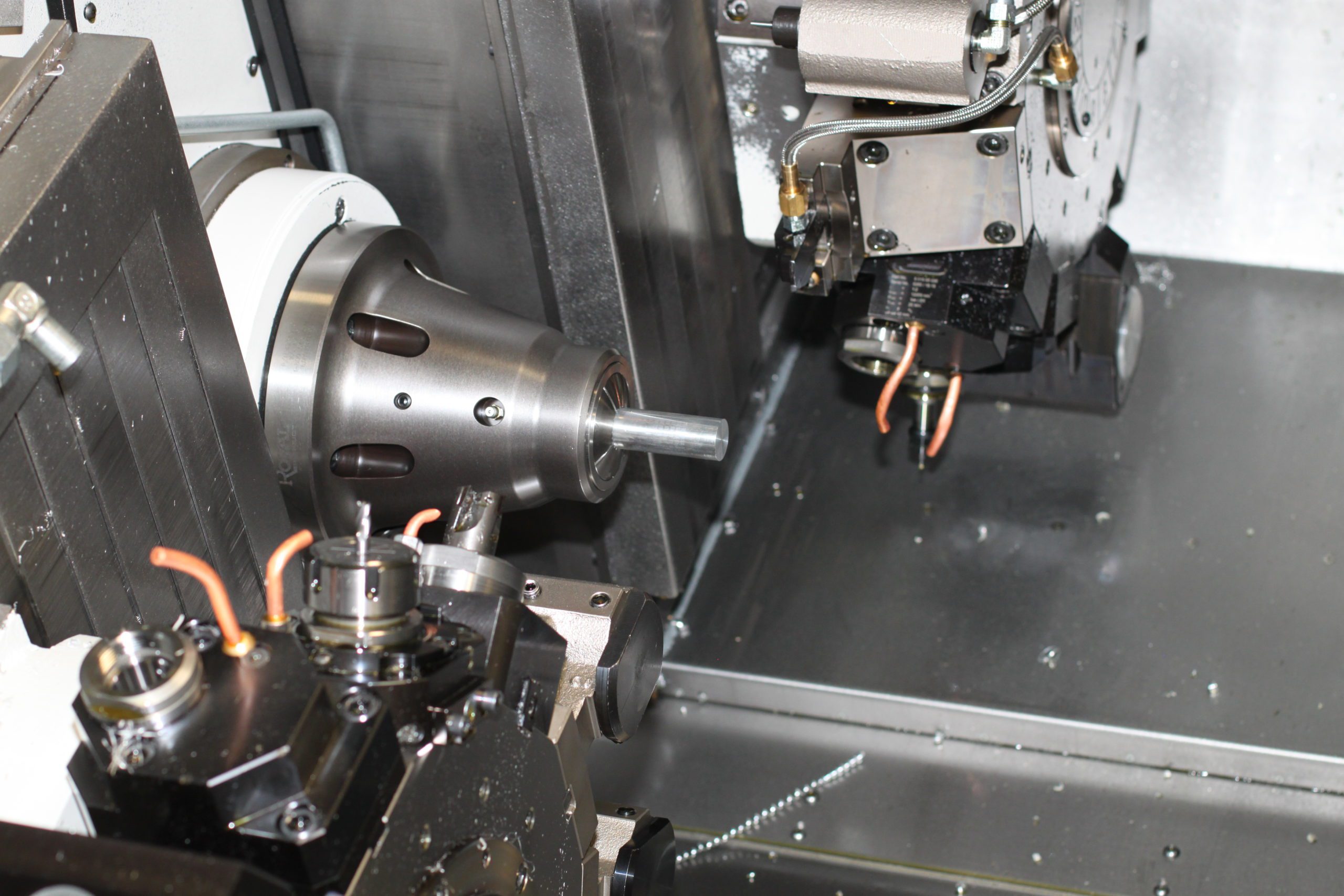

Our facility is equipped with a wide range of high-tech, multi-axis machinery with an impressive array of quality and productivity enhancing features, including automated bar feeds, live tooling for milling and cross drilling, as well as secondary spindles for back working operations.

We can work with all materials, including standard metals, high-performance alloys, as well as plastics, we have the capacity to turn parts measuring up to 4.0” in diameter while achieving tolerances of ±.0001” with excellent surface finishes. We have the resources to implement dedicated work cells that cost effectively manage processes with demonstrated flexibility and efficiency.

We stand firm in our commitment to quality and hold several credentials, including ISO 9001, AS 9100, ISO 13485 certifications, and ITAR/JCP registration. We also supply parts that satisfy the requirements for all PPAP levels. Along with custom stocking programs, we offer Just-In-Time (JIT) delivery and EDI services to accommodate your inventory management strategies. More detailed information about our comprehensive CNC lathe machining services can be found in the table below. Contact us at any time for a quote on your next project.

- Machining Processes

-

- Milling

Drilling

Precision Boring

Turning

Tapping

Thread Milling

Knurling

Counterboring

Countersinking -

Reaming

Parting/Cutting

Facing

Pick Off Capabilities

Broaching

Slotting

External Thread Cutting

Internal Thread Cutting

- Milling

- Equipment

-

- CNC Lathes

- (5) Eurotech B.65-Y2

- (3) Miyano ABX-51TH3

- (3) Mazak HQR-200MSY

- (2) Miyano ABX-51SY

- (2) Miyano ABX-645Y

- (2) Eurotech B.65-Y3

- (1) Hardinge CS-GT

- (1) Hardinge SG-42

- CNC Lathes

- Machine Shop

-

- Rockwell Band Saw

- Sweco Finishing Mill

- Beere Tipshear

- (3) Hardinge Hand Screw

- J.F. Burns Chamfering Machine

- Kalamazoo Band Saw

- JET Engine Lathe

- (2) ProTrak Vertical Miller

- (4) Bridgeport Vertical Miller

- Sunnen Honing Machine

- Harig Surface Grinder

- Clausing Covel Surface Grinder

- Agathon Surface Grinder

- (2) Kira CNC Vertical Miller

- Machinery Axis

- 5th axis

Live Tooling

- Part Diameter

- Up to 2-3/4 in Through the Spindle

Up to 4 in when Chucking

- Tolerances

- ± .0001

- Materials

-

- Super Alloys

Titanium

Alloy Steels

Stainless Steel

Carbon Steel

Brass - Aluminum

Copper

Delrin

Ultem

All Plastics

- Super Alloys

- Secondary Services Offered

-

- CAD Design Services

CAM Programming Services

Assembly

Parts Washing - Vapor Degreasing

Laser Marking

Laser Welding - Approved Vendors For:

- Grinding

- Plating

- Passivating

- Heat Treating

- Anodizing

- CAD Design Services

- Production Volume

-

- Minimum 500 Parts

Customized Inventory Stocking Programs:- J.I.T

- KanBan

- EDI

- Minimum 500 Parts

- Focused End Markets

-

- Aerospace

Industrial Automation

Medical

Microwave

Electro-Optical/Infrared/Thermal Imaging

Flow Control - Military

Defense

Robotics

Oil & Gas

Semiconductor

- Aerospace

- File Formats

-

- AutoCAD (DWG,DWZ)

DXF

CADL

PDF

SolidWorks (SLDPRT,SLDDRW,SLDDRT)

X_T Parasolid Text - X_B Parasolid Binary

SLDPRT SolidWorks

TPT AutoDesk Inventor

STL

ProE

STEP

- AutoCAD (DWG,DWZ)